Remove blockage in your Heat Transfer Fluid System

See an immediate 15 – 35% improvement in fuel efficiency after cleaning and flushing!

Most of the heat transfer systems our Lubrication Engineers have encountered only add oil when low. The norm is to ignore the condition of the thermal fluid and interior heat transfer surfaces.

Can you imagine what your car/truck engine oil would look like after 20 years of operation without changing the oil or oil filter? Would your engine last that long?

We can help you...

- Be less prone to emergency shutdowns

- Promote system with close to “new” thermal conductivity for best fuel efficiency

- Promote the best products for your system

- Improve your bottom line

SERVICES:

- 50 point heat transfer system inspection with specific recommendations for your plant

- Perform thermal fluid analysis and interpretation to determine quantity and type of contaminants

- Sales of the best “safe and effective” thermal system cleaners that remove liquid asphalt, coked-on carbon and varnish from the interior of thermal systems.

- Supervision of plant personnel for cleaning, flushing, refilling and fluid analysis procedures of thermal system to maintain high thermal conductivity rates

- Training seminar for all division Strategic Sourcing Specialists covering typical heat transfer problems in asphalt plant operations, the role of oil analysis in heat transfer fluids and projected bottom line savings.

- Train operators/maintenance regarding regular fluid maintenance and fluid sampling procedures, etc.

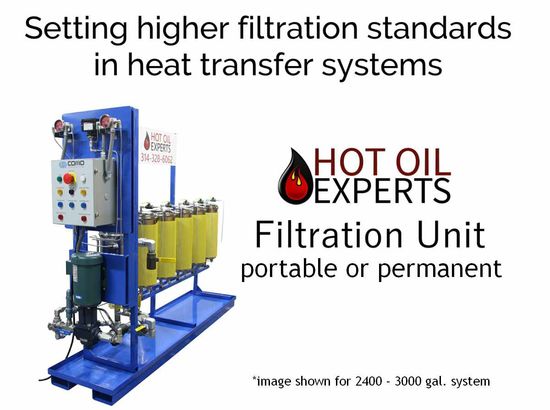

- Direct sales of effective filtration systems, based on application